The hydraulic high-power generator developed by our long experience and technology.

High-power generator

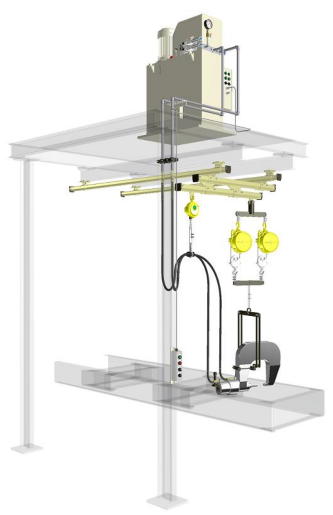

The hydraulic high-power generator developed with our long experience and technology is widely used by truck manufacturers in Japan, China, and around the world for “cold riveting” of rivets during chassis assembly.

Special feature

- The pump is designed for high speed, high pressure, and minimal motor output (5 times the general hydraulic pump output) to achieve energy savings.

- The design minimizes heat generation from oil temperature to achieve energy savings.

- Since the pump rotates in oil, there are no problems such as insufficient suction, and it is used with a safety factor of twice the normal working pressure, so it can be used for a long period of time with peace of mind.

- Each operating valve is designed to be trouble-free, easy to adjust, and easy to maintain.

- Bending, warping, riveting, etc. can be quickly and easily performed by connecting a simple hydraulic tool to this unit.

- Operation is performed with the push button station on hand, and the unit returns to the origin when the push button station is released, so it can be used safely.

- This can also be used for marking and punching machines.

High-power generator

Introduction Video

High-power generator and Riveter

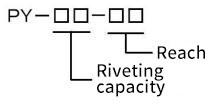

YGW sireis &PY series

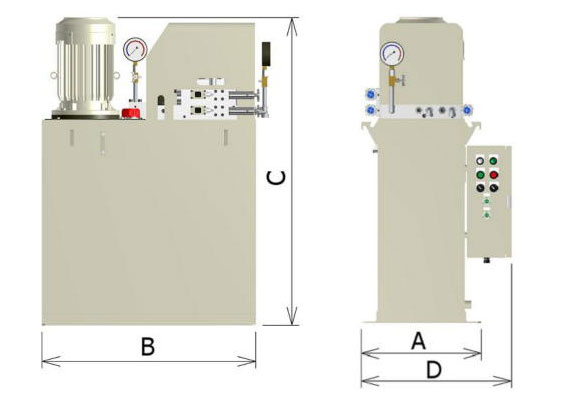

Speficication

| The hydraulic generator type | Pump capacity | Motor capability (kW×P) |

Booster capability 〔cm3〕(MPa) |

Oil tank capacity(L) | External pipe | Weight (oil-containing)(㎏) |

Main dimensions(mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| pressure (MPa) |

Dispense volume (L/min) |

Hose (Rc) |

Pipe (Rc) |

||||||||||

| 50Hz | 60Hz | 50/60Hz | A | B | C | D | |||||||

| YGW-50 | 7 | 65 | 78 | 7.5×4 | 〔600〕35 | 260 | “1/2 | “3/4 | 700 | 540 | 980 | 1275 | 680 |

| YGW-40 | 44 | 53 | 5.5×4 | 〔400〕35 | 200 | 620 | 500 | 900 | 1335 | 640 | |||

| YGW-35 | 3.7×4 | 〔330〕35 | 600 | 500 | 850 | 1275 | |||||||

| YGW-18 | 31 | 37 | “3/8 | “1/2 | |||||||||

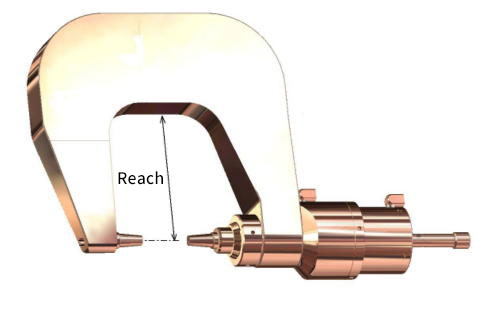

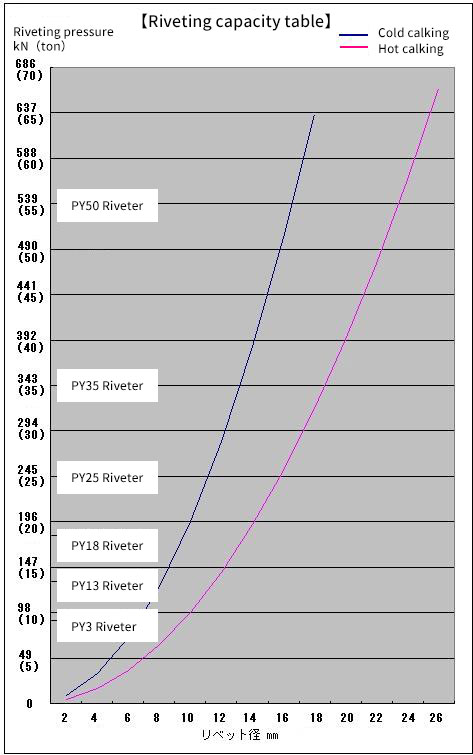

Riveter

Riveter type

Dimensions

| Type | Reach | Type | Reach | Type | Reach | Type | Reach | Type | Reach | Type | Reach |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PY-9-60 | 60 | PY-13-200 | 200 | PY-18-150 | 150 | PY-25-150 | 150 | PY-35-150 | 150 | PY-50-150 | 150 |

| PY-9-150 | 150 | PY-13-250 | 250 | PY-18-200 | 200 | PY-25-200 | 200 | PY-35-200 | 200 | PY-50-200 | 200 |

| PY-9-200 | 200 | PY-13-300 | 300 | PY-18-250 | 250 | PY-25-250 | 250 | PY-35-250 | 250 | PY-50-250 | 250 |

| PY-9-250 | 250 | PY-13-350 | 350 | PY-18-300 | 300 | PY-25-300 | 300 | PY-35-300 | 300 | PY-50-300 | 300 |

| PY-9-300 | 300 | PY-13-400 | 400 | PY-18-350 | 350 | PY-25-350 | 350 | PY-35-350 | 350 | PY-50-350 | 350 |

| PY-18-400 | 400 | PY-25-400 | 400 | PY-35-400 | 400 | PY-50-400 | 400 |

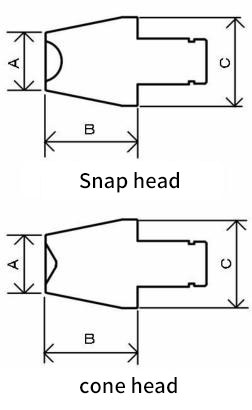

Snap for portable riveter

Snap shapes include button head, cone head, and flat head, etc.. Snaps can also be manufactured to suit the user’s usage situation. All snaps are made of special steel by heat treatment.

Dimensions

| Rivet diameter | A | B(mm) | C | ||

|---|---|---|---|---|---|

| Min | S.T.D. | Max | |||

| φ5 | 13 | 13 | 26 | 38 | 28 |

| φ6 | 16 | ||||

| φ8 | 19 | 13 | 32 | 50 | 32 |

| φ10 | 22 | ||||

| φ12 | 27 | 20 | 40 | 57 | 40 |

| φ13 | 30 | 26 | 50 | 75 | 48 |

| φ16 | 38 | 32 | 60 | 90 | 58 |

| φ19 | 45 | - | - | - | - |

| φ22 | 50 | - | - | - | - |

| φ25 | 58 | - | - | - | - |