NC high-speed notching machine for stator core and rotor core throat punching of motors.

NC high-speed notching machine/

Fully automatic NC high-speed notching machine

YN series

This machine is a spindle type machine designed for slot punching of stator cores and rotor cores made of laminated steel sheet, which are mainly required for the manufacture of electric motors and generators. The indexing is done by NC indexing. Indexing is done by NC indexing.

High-speed notching machine

This product was the trigger of the start of YOSHINO’s entry into the motor industry.

The technology cultivated over 60 years in the press and forging industry is utilized in every detail.

Completed in 2004, we are proud of our achievements more than 60 units in total.

- Product lineup includes 6-ton and 12-ton

- Special specifications are also available (actual examples: 8-ton, 10-ton, and 20-ton specifications)

- Contributes to the production of high quality medium and large electric motors.

- Environmentally friendly equipment. The main power source is a servo motor.

- NC indexing method is used for indexing.

- Full automation is also available according to customer requirements.

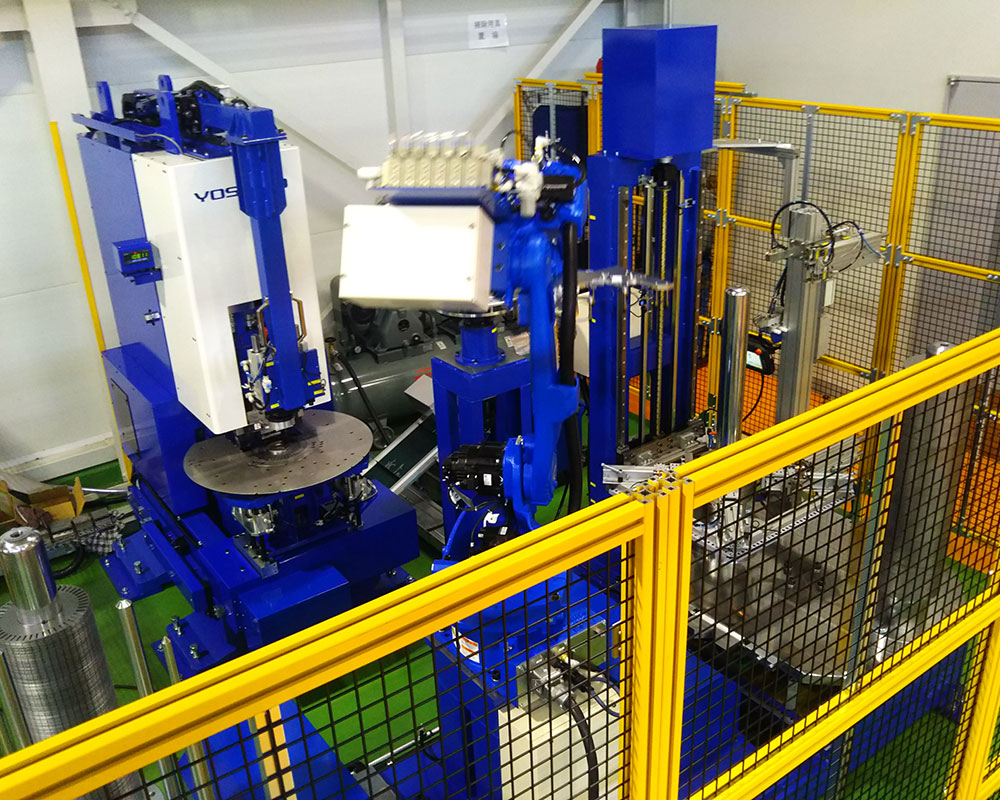

Fully automatic NC high-speed notching machine

Automation, labor saving, and systemization contribute to high precision and high production.

【Production line structure】

- Automatic linear conveyor system

or robot transport - Blank stacker rotary type

- Floating pickup device

- Orientation device

- NC high-speed notching machine

- Stator stacker rotary type

- 2-piece detection device

【Workpiece processing cycle time】

When punching with workpiece outer diameter 670mm and 96 slots 600spm

Approx. 15 sec/sheet

Special feature

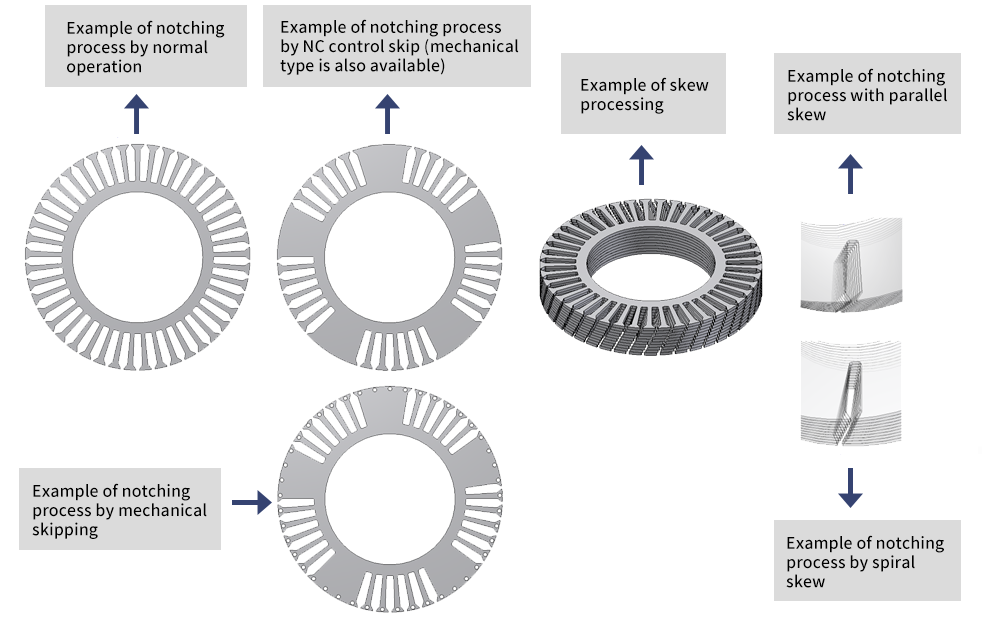

High-speed machining, ideal for high-mix, small-lot machining. Servo-driven notching (notch) machining rotates with high speed while maintaining The machine rotates at high speed while maintaining a controlled machining machine accuracy of ±5/100 and performs notching processing.

Notching process reference data

Notch work press punching test

| process | Standard notch |

|---|---|

| workpiece material | Non-directional electromagnetic steel plate |

| Thickness of steel plate | 0.5t |

| Sample | (1) A1-3 φ510 x 3pcs at 750spm (2) B1-3 φ810 x 3pcs at 800spm (3) C1-3 φ1000 x 3pcs at 800spm |

【Product repeat accuracy】

| Work Name | Number of slots | Number of errors | error ratio(%) | error range(Max/Min) |

|---|---|---|---|---|

| A1 | 60 | 17 | 28 | +0.02/0 |

| A2 | – | 12 | 20 | +0.02/-0.01 |

| A3 | – | 19 | 31 | +0.01/-0.02 |

| B1 | 72 | 18 | 25 | +0.01/-0.01 |

| B2 | – | 50 | 69 | 0/-0.02 |

| B3 | – | 46 | 63 | 0/-0.02 |

| C1 | 90 | 57 | 79 | +0.03/-0.03 |

| C2 | – | 63 | 70 | +0.03/-0.03 |

| C3 | – | 50 | 55 | +0.03/-0.02 |

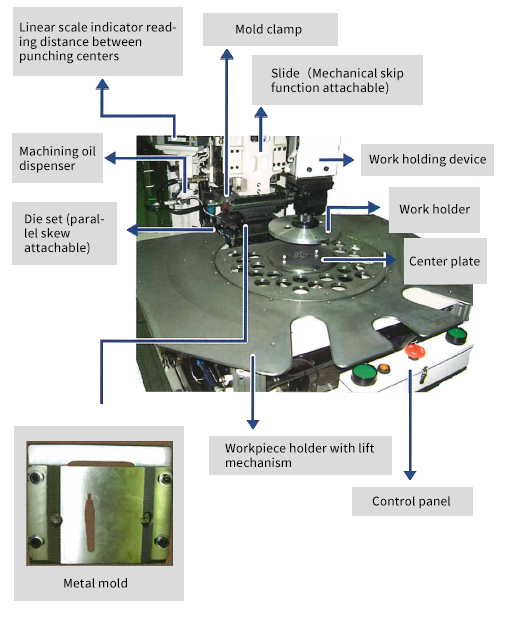

Notching machine processing part

Overview of Notching Process

Notching machine specifications

| Specifications/Model | YN6-7 | YN12-12 |

|---|---|---|

| capacity<kN> | 60(6t) | 120(12t) |

| Output point (above bottom dead center)<mm> | 1.5 | 1.5 |

| Slide stroke number<spm> | 100~600 | 200~600 |

| Slide stroke length<mm> | 20 | 25 |

| Slide adjustment amount<mm> | 25 | 25 |

| die-height<mm> | 223 | 223 |

| Index range | 4~200 | 4~200 |

| Slide area(L×R)<m㎡> | 120×120 | 180×120 |

| Bolster Area (F×B)<m㎡> | 360×220 | 360×230 |

| Max. blank thickness<mm> | 0.5~1.0 | 0.5~1.0 |

| Max. blank diameter<mm> | 700 | 1200 |

| Min. blank diameter<mm> | 120 | 400 |

| Frame gap<mm> | 280 | 360 |

| Main electric motor<kw> |

7.5 | 11 |

Please feel free to contact us for specifications other than those listed above, as we may be able to respond your demand.

Equipable functions

- Die set

- Mold clamp (hydraulic type)

- Mechanical skip function

- Parallel skew device and spiral skew function

- Machining oil dispenser

- Work holding device

- Workpiece holder with lift mechanism

- Linear scale indicator reading distance between punching centers

- IOT Monitoring System

Introduction Video

NC high-speed notching machine

Fully automatic NC high-speed notching machine