AC servo motor-driven panel bending machine with ease of use, high-speed processing, high accuracy, and stable production.

Servo Drive Panel Bender

/YSB series

Special feature

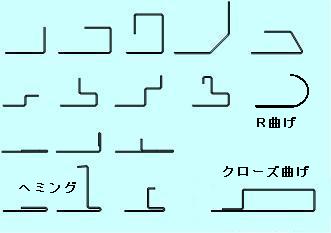

Example of workpiece cross-sectional shape

Various bending shapes can be processed.R bending can be handled by using the upper die for R bending or feed (pitch) bending.

Simple entry

Bending shapes can be input by touching directly on the screen. After input, the dimensions of each side can be easily corrected.

Example of workpiece bending

Here are some examples of bending various panel steel sheet workpieces.

The Servo Drive Panel Bender has eliminated the need for protective sheets,

which was considered impossible with the conventional shigoki- bending

process.

Even with materials without protective sheets, flaws and delamination

can be significantly reduced, contributing to lower material costs,

fewer defective products, and reduced manufacturing processes.

Bending of panel steel sheets 0.5 to 0.6 t thick is possible, and small

flange bending is also possible. Yoshino Machinery Corporation

will make various proposals to solve customers’ bending problems

based on test data and actual results. In addition to the bending examples

below, test data for various workpiece materials and dimensions are available.

AC servo motors on all axes

Since it does not use hydraulic pressure, it is maintenance-free, including hydraulic oil replacement. No oil temperature changes have any effect on the machine, and noise and vibration during operation have been greatly reduced. Furthermore, it is more energy-efficient than hydraulic systems.

No workpiece flip-up

Forward bending, reverse bending, hemming, etc. are possible without bouncing the workpiece.

Semi-automatic system

The operator only needs to position the material against the stopper, and the machine performs the folding process on all sides in a semi-automatic manner, and the operator only needs to carry in/out the material and handle the handling of the material by bumping and rotating.

Automatic length of punch changner (Tool Length Changer)

The upper tools can be automatically switched to the size that matches the bending length. The upper die is switched at a pitch of 5 mm, allowing switching according to the workpiece length. For the sleeve section, an open type is used. Also, R type tip, closing type, etc. can be installed as an option.

Simple one-person operation

Panel bending work can be performed by a single operator without workpiece buckling, even with thin panels and long lengths.

Specification

YSB2000/YSB2500/YSB3000

Introduction Video

YSB Bending Demonstration

YSB die image

YSB TLC image