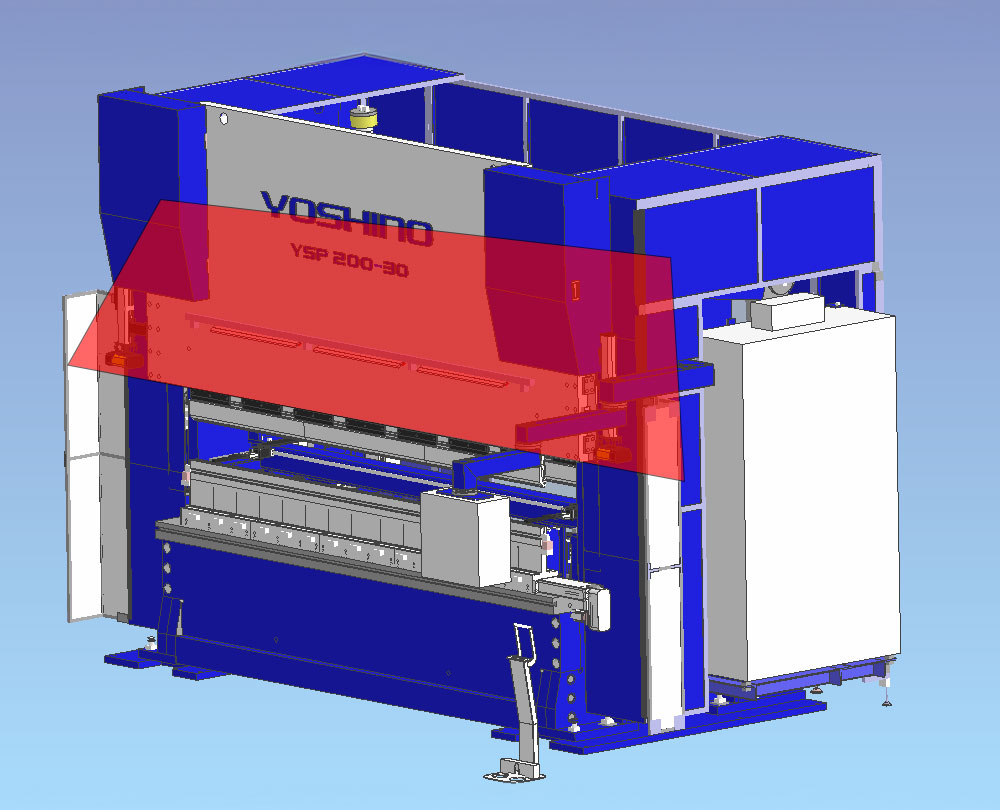

The newly conceived AC servo press brake YSP, which combines high precision, energy saving, and high cost performance, has been proudly introduced to the series.

AC Servo Press Brake /

YSP Series[Patent] No. 6104848

The YSP series has achieved significant power savings, quieter operation, and lower vibration compared to conventional hydraulic and hybrid types. Furthermore, the machine achieves a power of over 100 tons and a bending length of 6 m, which were considered challenges for conventional AC servo press brakes. Machining accuracy is outstandingly high thanks to the high precision characteristic of AC servos and the overwhelming mechanical rigidity of YSP.The peripheral equipment is also well equipped, with the QTC system being particularly effective. Workpieces that were being processed by several machines can be consolidated into a single machine, which eliminates the need for horizontal material transfer and intermediate stocking, thus realizing high work efficiency in a small footprint.

Feature

AC servo, from small machines to high power machines with QTC.

Remarkable performance that makes a big difference in the field.

- The size of the motor capacity has been reduced to 1/3 of the conventional size with minimum energy and maximum effect by the link mechanism.

- Eccentric offset system increases ram descent speed.

- No hydraulic mechanism is used to drive the ram, greatly improving quietness, low-vibration performance, and power-saving performance.

- Standard support for an amazing open height of 600mm. More than 600mm is available as an option (we have experience with 880mm).

- Basic structure with low distortion by increasing the rigidity of the ram and bed and reducing the frame gap to a maximum 150 mm or less.

- One-touch clamps are used for easy clamping of punches.

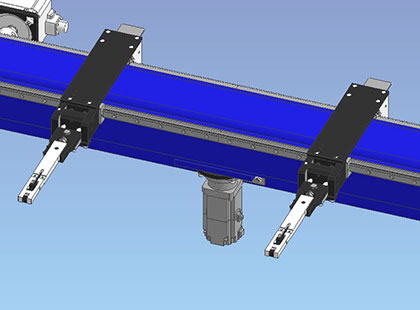

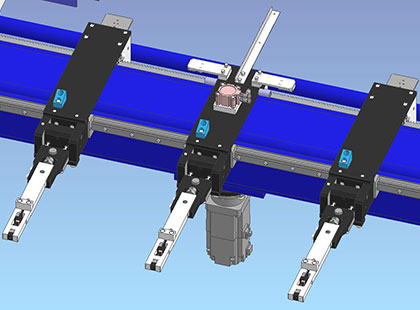

QTC(Quick Tool Changer)

- Three types of upper punches and three types of lower dies are automatically exchanged at high speed respectively, Tooling set up time drastically are reduced.

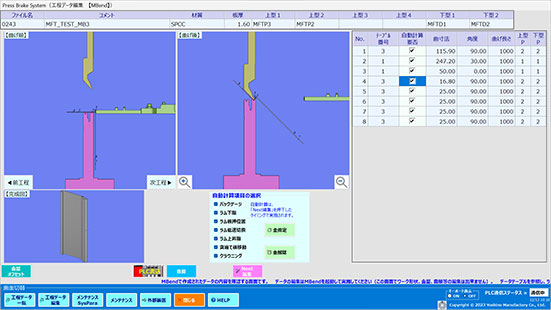

YSP CNC control

- Color touch panel for easy operation.

- Three patterns are supported: direct input, angle direct input, and shape input.

- Linkage with upper-level production management system *Optional (specifications to be discussed)

High performance back gauge

- Equipped with two thrusting units. NC control of forward /backward, left/right, and up/down.

- Supports up to 5 axes as standard. Up to 4 axes are supported for bending lengths less than 3 m.

- Optional butt-attachment expansion, butt-attachment confirmation sensor, etc. are available.

Various optional devices

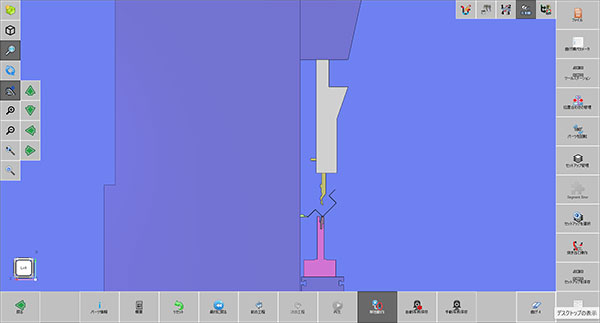

3D graphic simulation software

Automatic tooling selection, bending sequence and collision check functions allow you to check the simulation of bending before machining. Can be add-in to CAD software. Raw 3D CAD data can also be used without modification.

Crowning compensator

Compensates for variations in angle and shape due to mid-range sagging, etc. (Standard for manual type. Automatic type is also supported.)

Special Dies

We also design and manufacture dies with special shapes that are not included in standard dies.

Material flip-up follow-up device

Eliminates banzai work, which is burdensome for the operator, and prevents defective products due to waist breakage.

Material support (receiving) device

Support (receiving) devices are installed in front of the work (front) and inside the machine (rear) to assist work. It reduces the operator’s workload, prevents materials from falling inside the machine, and prevents back gauge sticking defects.

Safety device

Laser and optical safety devices are available to deter the occurrence of hazards.

Transport equipment, robots, etc.

Material handling equipment can be installed and robots can be used to automate processing. We offer a wide variety of equipment that only a specialized machinery manufacturer can provide.

Specification

AC Servo Press Brake

YSP 40-13/60-20/120-30/120-40/200-30/200-40/300-40/300-50

Introduction Video

AC Servo Press Brake YSP 60-20

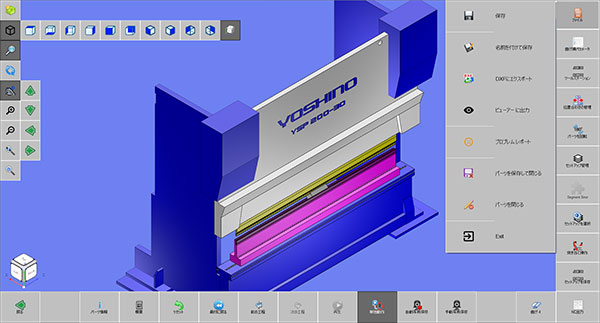

AC Servo Press Brake YSP200-30

YSP Series