Custom-made products

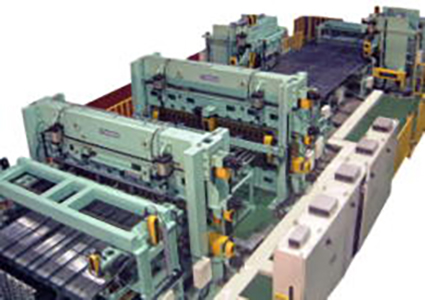

Automatic labor-saving production line

We will design and manufacture the product to meet the specifications

according to customer’s demand and take full responsibility

until the production line flows smoothly.

Steel panel bending line

A production line that sequentially bends

four pieces of steel plate panels of various sizes.

| Thickness | 0.4~0.8mm |

|---|---|

| Material | SPCC・Decorative steel plate |

| Bending size | 300×200mm~3000×1500mm |

| Machining flange | 4~40mm |

| Bending angle | 90° |

| Bending outer R | Plate thickness×2.2R (at 0.5t) |

| Bending drive system | Servo motor |

Bathtub wall panel bending line

A production line that sequentially folds the short sides of bathtub wall panels, which can be bent to match various workpiece shapes.

| Thickness | 0.6mm |

|---|---|

| Material | Decorative steel plate |

| Bending length | Max1200mm |

| Bending angle | 90° |

| Bending outer R | Plate thickness×2 |

| Bending drive system | Servo motor |

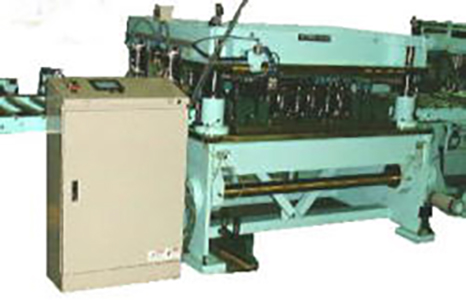

Stand-alone machine (Dedicated machine)

We introduce our products (specialized machines) designed

and manufactured in response to various customer requests.

Transfer press machine

A 3-station separate type hydraulic press machine with automatic feeder.

| Number of Stations | 3 |

|---|---|

| pressurizing capacity | 500kN×3 |

| Driving method | Hydraulics |

| Stroke length | 300mm |

| Bolster Area | 700mm×300mm×3 |

| Length between stations | 500mm |

| Transfer method | By adsorption pad |

Roll Forming Hydraulic Press

A hydraulic press machine that roll-forms materials in several stages.

| pressurizing capacity | 700kN |

|---|---|

| Driving method | Hydraulics |

| Stroke length | 150mm |

| open height | 650mm |

| Bolster Area | 770mm×800mm |

| Roll propulsion unit | |

| Max. propulsive power | 150kN |

| Max. stroke | 300mm |

W-crank wide bed transfer press

A mechanical press machine with an automatic

feeder that gradually draws the workpiece in several processes.

※Tonnage head widths are available according to customer specifications.

| pressurizing capacity | 500kN |

|---|---|

| Driving method | inverter |

| Stroke length | 150mm |

| Number of strokes | Max. 60SPM |

| Shut height | 290mm |

| Ram Adjustment | 60mm |

| Bolster Area | 1400mm×500mm |

Shell punch & Chamfer automatic processing machine

An automatic punching machine with generator that punching is performed in four steps while facing the shell-shaped workpiece.

| Number of Stations | 5 |

|---|---|

| Punch pressurization capacity | 150kN×1 75kN×4 |

| Driving method | Hydraulics |

| Length between stations | 600mm |

| Transfer method | By clamping chuck |

| Cycle time | 7sec |

Blanking press

Special press machine for punching long materials by moving them in one direction.

| pressurizing capacity | 200KN |

|---|---|

| Generation position | 3mm |

| Driving method | Servo motor |

| Stroke length | 50mm |

| Number of strokes | 40spm |

| Carriage movement amount | 500mm |

4-wing bender

A 4-wing bender performs R-shaped bending of electrical appliance exterior panels, etc.

| Bending length | 755mm |

|---|---|

| End bending | 636mm from box bend |

| Box bending | 610mm |

| Thickness | 0.8t |

| Material | PCM steel plate |

| Bending R | End bending 15R、Box bending60R |

Hydraulic driven panel bender

A panel bender that bends and forms the four outer edges of panel-shaped products.

| Thickness | 0.6~0.8mm |

|---|---|

| Material | SPCC・Decorative steel plate |

| Bending length | Max. 2100mm |

| Machining flange | 5~40mm |

| Bending angle | 90° |

| Bending outer R | Plate thickness×2 |

Tangent bender

Specialized bender that forms the corners of exterior panels such as PCM steel plates into a downward R shape.

| Thickness | 0.8mm |

|---|---|

| Material | PCM steel plate |

| Bending length | Max. 1200mm |

| Bending outer R | 25mm |

| Bending method | Reverse bending Tangent Bender |

| Machining time | 15sec |

| Driving method | Hydraulics |

| Others | With take-out device |

Automatic Terminal Assembling Machine

An automatic assembly machine that inserts and assembles small terminals.

| Cycle time | 18sec/pc |

|---|---|

| Number of parts | 12 points/pc |

| Workpiece type | 5 kinds/pc |

| Parts supply | Parts feeders, Conveyors |

| Work-positioning | Servo motor, Fiber sensor |

| Work-transfer | Stepping motor, Air cylinder |

| Others | Automatic discharging of NG products in each process |